Laminated Glass

Product Introduction

PVB laminated glass is a special glass made by sandwiching a layer of polyvinyl butyral (PVB) film between two or more pieces of glass, and then bonding them under high temperature and high pressure. This glass not only inherits the high strength and impact resistance of tempered glass, but also integrates the explosion-proof, sound insulation, and UV protection characteristics of laminated glass.

Production Process

1. Material selection Select high-quality glass sheets and select the required thickness according to requirements.

1. Glass cutting Precise cutting to ensure cutting quality and accuracy.

2. Glass edge grinding Fine grinding, edge grinding of cut glass to eliminate sharp edges and fine cracks and improve edge smoothness.

3. Washing and drying Wash the edged glass to remove dust, oil and impurities on the surface to ensure subsequent bonding. Drying is required after washing to prevent moisture from affecting subsequent processing.

4. Tempered The principle is to form a layer of compressive stress on the surface of the glass to avoid glass breakage, so as to improve the strength of the glass, and better resist breakage. Even if it breaks, it is small particles, which greatly reduces the possibility of injury.

5. Lamination and pressing After cleaning, the glass and the film are laminated, initially pressed, and firmly bonded together with high pressure and strong bonding force to ensure the quality and transparent effect.

In summary, the process of PVB laminated glass involves multiple key steps and links, and each step requires strict control of quality and process parameters to ensure the performance and quality of the final product.

Product Specifications

| Single-layer glass thickness | 5 mm, 6 mm, 8 mm, 10 mm, 12 mm, etc. |

| PVB film thickness | Common PVB film thickness has a variety of specifications such as 0.38~2.28mm, and the specific selection needs to be determined according to the purpose and safety performance requirements of the laminated glass. |

| Customized according to customer needs. | |

Application

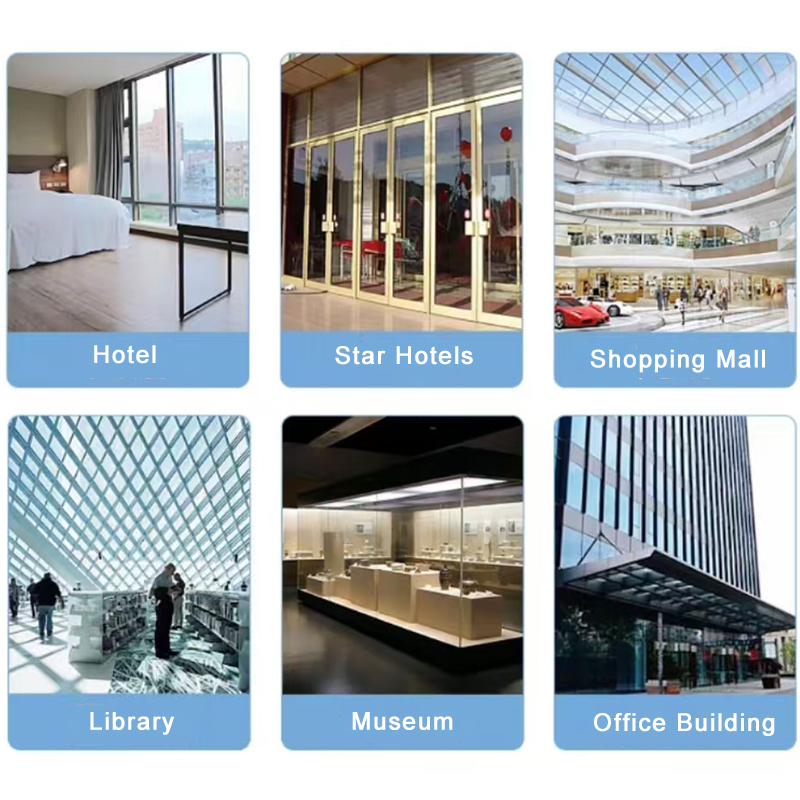

Used for doors, windows, curtain walls, partitions, etc. in public places such as schools, hospitals, shopping malls, and office buildings.

Technical Features

High safety, good sound insulation, energy saving and environmental protection, UV protection, beautiful appearance.

Our Services

Pre-sales service: provide samples;

Welcome to visit the factory; timely reply; professional sales team. Production cycle service: professional customization; timely update of progress; strict quality inspection;

Installation guidance: provide customers with installation guidance services for glass products to ensure the correct installation and use of the products.

After-sales service: regular follow-up; provide installation guide; solve after-sales problems in time.

FAQ

Q: Can the price be discounted?

A: According to your order quantity, if you order glass in large quantities, I can negotiate with the supplier and strive to get the best price for you.

Q: What certificates have you passed?

A: After identification by relevant professional institutions, the company has passed 3C certification, environmental protection system certification and other quality system certifications.

Q: What types of glass are there?

A: There are single-piece glass, laminated glass, hollow glass, fireproof glass, curtain wall glass, LOWE glass, etc. There are many varieties and they are customized according to your needs.

Q: What are the performances of the glass?

Answer: It has high safety performance, sound insulation and noise prevention, UV protection, heat insulation, energy saving and environmental protection, shock resistance and explosion resistance, etc.